Production Introduction of Logistics Box

Logistics boxes are essential components in the transportation and storage industry, facilitating the seamless movement of goods across various supply chains. The production process of logistics boxes is a meticulous endeavor that involves multiple stages to ensure the creation of durable, efficient, and sustainable containers for logistical operations.

1. Design and Planning

The production of logistics boxes starts with meticulous design and planning. Engineers and designers collaborate to create blueprints that outline the dimensions, materials, and structural features of the boxes. Factors like load capacity, stackability, and compatibility with handling equipment are carefully considered during this phase to optimize functionality.

2. Material Selection

One of the critical aspects of logistics box production is material selection. High-quality plastics, such as polyethylene (PE) or polypropylene (PP), are commonly used due to their durability, lightweight nature, and recyclability. These materials offer the necessary strength to withstand varying weights and environmental conditions while remaining cost-effective.

3. Injection Molding

The most common manufacturing technique for logistics boxes is injection molding. This process involves melting plastic resin pellets and injecting the molten material into a mold cavity under high pressure. The mold is then cooled and solidified, resulting in the desired shape and structure of the logistics box. Injection molding allows for mass production of boxes with consistent quality and precision.

4. Assembly and Finishing

After the injection molding process, the logistics boxes undergo assembly and finishing stages. Any additional components, such as lids, handles, or labeling systems, are attached to the boxes. Surface finishes, such as printing logos or QR codes for tracking purposes, are applied to enhance visibility and identification during transportation and warehousing.

5. Quality Control

Quality control plays a vital role in ensuring the reliability and performance of logistics boxes. Each box goes through rigorous testing procedures to assess factors like structural integrity, weight-bearing capacity, dimensional accuracy, and resistance to impacts and weather conditions. Quality control measures aim to meet industry standards and customer requirements for robust and dependable logistics solutions.

6. Packaging and Distribution

Once the logistics boxes pass through quality control checks, they are packaged according to customer specifications and prepared for distribution. Packaging methods ensure safe transportation of the boxes to various destinations, whether locally or globally. Efficient logistics management ensures timely delivery of the boxes to clients, warehouses, or distribution centers.

In conclusion, the production of logistics boxes involves a comprehensive process that blends innovation, precision engineering, and quality assurance to deliver reliable and sustainable solutions for the logistics industry. By leveraging advanced manufacturing techniques and materials, logistics boxes continue to play a pivotal role in streamlining supply chain operations and enhancing the efficiency of goods transportation worldwide.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL ID

ID SR

SR UK

UK VI

VI SQ

SQ HU

HU TH

TH TR

TR MS

MS IS

IS BN

BN LO

LO MN

MN NE

NE MY

MY UZ

UZ KY

KY

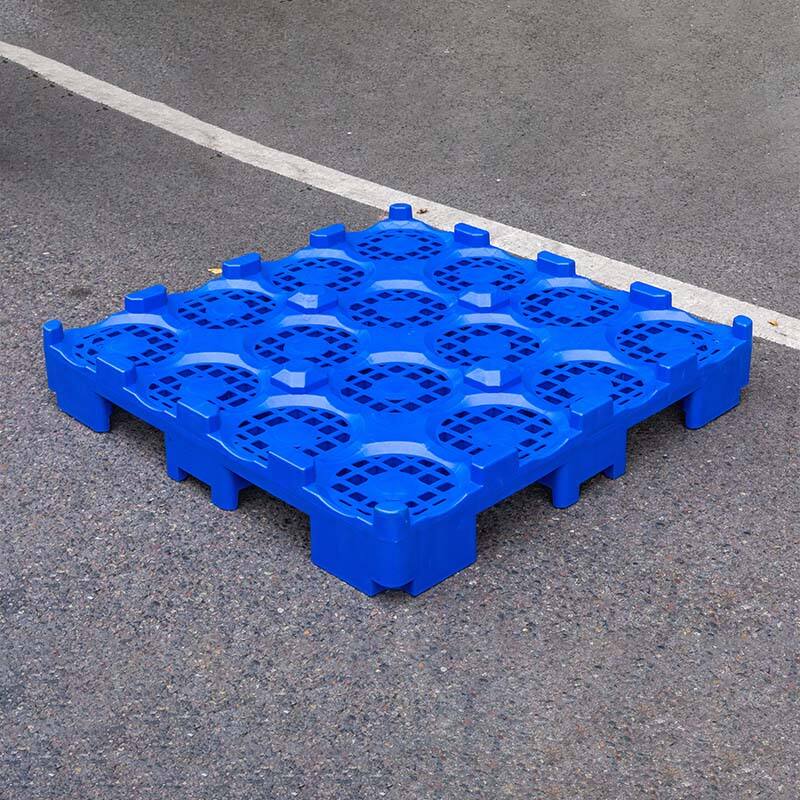

Plastic Pallets

Plastic Pallets Logistics Box

Logistics Box Plastic Crates

Plastic Crates Bulk Containers

Bulk Containers Trolly Cart

Trolly Cart Waste Bins

Waste Bins liquid storage containers

liquid storage containers Boat &Aquatic products

Boat &Aquatic products